| The Very Highest Quality Coins... |

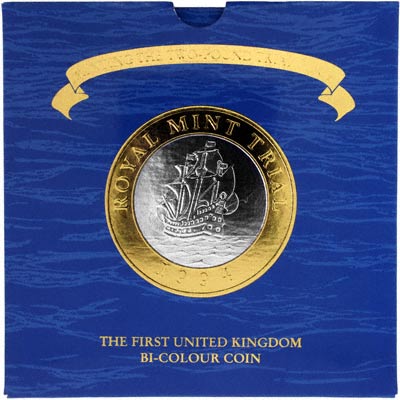

| 1994 £2 Royal Mint Trial Pack |

|

|

|

|

|

|

|

|

Production Method

First Stage - Alloying

The first stage in the manufacture of a two-pound coin is the melting and alloying of its constituent metals in electric induction furnaces at temperatures of between 1300° and 1400° Celsius. The bi-colour nature of the new coin means that two different alloys must be processed separately.

Continuous Casting

In either case, once examination by x-ray fluorescence spectrometry has confirmed that the alloy is correct, the molten metal is continuously cast, from a holding furnace, through water-cooled graphite dies. The emerging strip, 210mm wide by 15mm thick, is cut into manageable 10m lengths and its upper and lower surfaces are scalped by up to 0.50mm to remove oxide discolouration.

Rolling

Two passes through a tandem rolling mill reduce its thickness to 3mm and in so doing, double its length. Because the nickel-brass will now have become work-hardened, the strip must be softened by an annealing process of seven hours duration in a furnace at 600° Celsius. The strip is reduced to the desired thickness for coining by being accurately rolled on a reverse finishing mill. At this point the now extended strip has been accurately reduced to coin thickness.

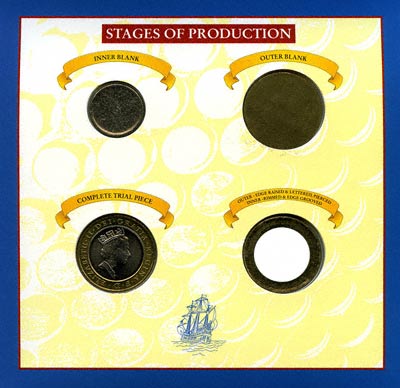

Punching Out the Blanks

Cupro-nickel and, at this stage, whole nickel-brass coin blanks are punched out of the strip at a rate if up to 5,000 per minute with a force of 100 tonnes. The metal residue from the blanking process, known as scissel, is returned to the furnace.

The blanks are softened in annealing furnaces operating at temperatures of up to 950° Celsius. After cooling they are fed into automatic blank finishing machines, where stains are removed by a solution of sulphuric acid. They are then burnished and finally rinsed in water and dried off.

Edge Rolling & Lettering

The outer blanks of nickel-brass are given raised edges by being rolled under great pressure between the fixed segment and rotating wheel of a rimming machine. It is also at this stage that the coin's edge lettering is applied. Central holes, which take the smaller cupro-nickel blanks, are punched out on a piercing press. The rimmed inner blanks meanwhile receive an edge groove as a key to bonding.

Striking the Coins

A coining press is served by two separate hopper and feed systems for the different blanks. The first system feeds the pierced outer blank into a dial plate segment, which then moves on to the second operation. there the inner blank is dropped into position, loosely located inside its outer. Held by the segment, the coin parts pass on to be brought to rest on top of the lower die, whose upward movement pushes the blanks into a restraining collar. Continued upwards movement of the lower die squeezes the blanks against the upper one with a 100 ton force, so that both impressions are received in a single operation. By the same action the metal, being forced outwards, takes up the pattern of the milled collar, and the union of the two coin parts is made.

The completed bi-colour two-pound coin is ejected from its collar by a downward movement of the upper die.

Obverse

The Third Portrait

The obverse (head side) bears the third major portrait of Queen Elizabeth II, designed by Ralph David Maklouf, FRSA.

It came into use in 1985 and continued until 1997 inclusive, a total of thirteen years.

The queen is shown wearing a pearl necklet. In the second year of issue 1998, the portrait changes to the fourth portrait, showing more mature features, and without the necklet. Please see "The Two Pounds Story" for details of the quite unfounded rumour.

Reverse

In the centre, a three-masted sailing ship, similar to that previously used on halfpennies of George VI and Elizabeth II, the outer ring bears the inscription:-

ROYAL MINT TRIAL

1994

Edge

DECUS ET TUTAMEN ANNO REGNI XLXVI

The edge is milled and also carries an incuse inscription.

The edge inscription translates as "An ornament and a safeguard" - "The 46th year of (her) reign (=1998).

| If you wish to buy this product you will be redirected to www.chards.co.uk |

|

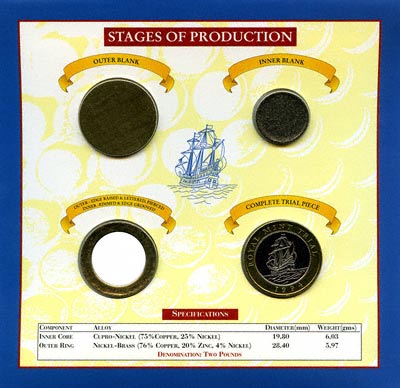

Technical Specifications - Base Metal Issue

| Alloy | Inner Disc | Cupro-nickel |

| Alloy | Outer Ring | Nickel-brass |

| Diameter | 28.40 mms | |

| Weight | 12.00 grams | |

Prices & Availability

All prices on our websites are subject to fluctuation and availability. Please check before ordering.

| Version | Grade | Qty Issued | Availability | Price £ | Price $ |

| Specimen in Folder | Brilliant Uncirculated | 4,565 | No | £175 | $125 |

Postage & Packing:

UK: At buyer's Risk £3.50 or

Fully Insured £9 (Usually by Royal Mail Special Delivery)

USA: Airmail at buyer's risk $10 or

Fully Insured $20

For further details, please see our Postage & Packing page.

Airmail to USA $10

Order Form - UK

Order Form - USA

Order Form - EU

Order Form - Rest of World

If you want to find the value of a coin you own, please take a look at our page I've Found An Old Coin, What's It Worth?

Or you could check out our £2 Coin Values page.

If you have an enquiry about any of our £2 Pieces, we'd be happy to answer you, but please note it may be quicker to telephone us. Please see the Contact Us page of our website.

Please, if you are going to ask us whether the £2 coin you own is worth more than £2, please, please, please read our other pages about them first, and even then the answer is almost certainly no. About 1,000 people every week read one or more of our pages about £2 coins. Hopefully most manage to find what they wanted. A tiny percentage, but still about 20 per week ask us whether a £2 they have found in change / in a drawer / been given is worth more than £2. The answer to 99% of these questions is already on our site. We do not have the time or patience to answer such questions individually.

| ...at the Lowest Possible Price |

|

32 - 36 Harrowside, Blackpool, Lancashire, FY4 1RJ, England. Telephone (44) - (0) 1253 - 343081 ; Fax 408058; E-mail: The URL for our main page is: https://24carat.co.uk | Chard(1964) Ltd |