| Year 2000 Coin Specifications... |

| Details of the Year 2000 British Coin Designs |

|

|

|

|

|

|

|

|

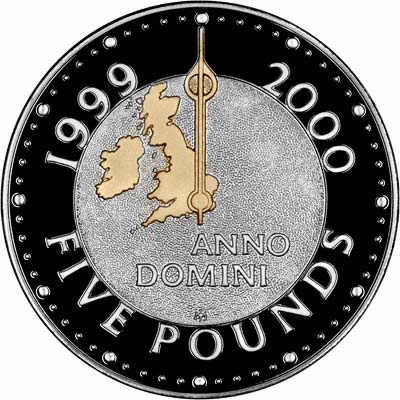

£5 Crown - Millennium Design

Similar in design to the 1999 issue millennium crown, except for the date 2000 on the obverse instead of 1999.

| Reverse | British Isles as Clock Dial |

| Designer | Jeffery Matthews; modelled by Robert Evans |

| Alloy | Cupro-nickel; 75% Copper, 25% Nickel |

| Diameter | 38.61 mm |

| Edge Thickness | 3.20 mm |

| Weight | 28.28 grams |

£2 Coin - Two Pounds

At the forefront of modern minting techniques is the bi-colour £2 coin. Its appearance in 1997 made it the first bi-colour coin for the United Kingdom, although the Royal Mint had produced such coins for overseas customers for years. The edge inscription "STANDING ON THE SHOULDERS OF GIANTS", is taken from a letter of Sir Isaac Newton, Master of the Mint from 1699 until his death in 1727, and is a reminder that the marvels of modern technology have been built on the accomplishments of previous generations.

| Reverse | Symbolic of the advance of technology. |

| Designer | Bruce Rushin |

| Alloy - Inner Disc | Cupro-nickel; 75% Copper, 25% Nickel |

| Alloy - Outer Circle | Nickel-brass; 76% Copper, 4% Nickel, 20% Zinc |

| Diameter | 28.40 mm |

| Edge Thickness | 2.50 mm |

| Weight | 12.00 grams |

£1 Coin - One Pound

The £1 coin features the Welsh dragon passant, part of the second series of reverse designs for the £1 representing the constituent parts of the United Kingdom. Like the previous £1 coins honouring Wales, this year's coin carries as an incuse edge inscription the words "PLEIDIOL WYF I'M GWLAD" (True am I to my country) from the Welsh national anthem.

| Reverse | The Royal Badge of Wales, the Welsh dragon passant. |

| Designer | Norman Sillman from a drawing by the College of Arms |

| Alloy | Nickel-brass; 70% Copper, 5.5% Nickel, 24.5% Zinc |

| Diameter | 22.50 mm |

| Edge Thickness | 3.15 mm |

| Weight | 9.50 grams |

50p - Fifty Pence - Public Library Commemorative

The striking of commemorative coins has become a regular feature of the United Kingdom coinage. The latest is the 50p coin of 2000 celebrating the 150th anniversary of the Public Libraries Act of 1850.

| Reverse | The turning pages of a book above a classical library building. |

| Designer | Mary Milner Dickens |

| Alloy | Cupro-nickel; 75% Copper, 25% Nickel |

| Diameter | 27.30 mm |

| Edge Thickness | 1.78 mm |

| Weight | 8.00 grams |

50p - Fifty Pence - Definitive

| Reverse | The seated figure of Britannia. |

| Designer | Christopher Ironside |

| Alloy | Cupro-nickel; 75% Copper, 25% Nickel |

| Diameter | 27.30 mm |

| Edge Thickness | 1.78 mm |

| Weight | 8.00 grams |

20p - Twenty Pence

| Reverse | The Badge of England, a Tudor rose royally crowned. |

| Designer | William Gardner |

| Alloy | Cupro-nickel; 84% Copper, 16% Nickel |

| Diameter | 21.40 mm |

| Edge Thickness | 1.70 mm |

| Weight | 5.00 grams |

10p - Ten Pence

| Reverse | A lion passant guardant royally crowned. |

| Designer | Christopher Ironside |

| Alloy | Cupro-nickel; 75% Copper, 25% Nickel |

| Diameter | 24.50 mm |

| Edge Thickness | 1.85 mm |

| Weight | 6.50 grams |

5p - Five Pence

| Reverse | The Badge of Scotland, a thistle royally crowned. |

| Designer | Christopher Ironside |

| Alloy | Cupro-nickel; 75% Copper, 25% Nickel |

| Diameter | 18.00 mm |

| Edge Thickness | 1.70 mm |

| Weight | 3.25 grams |

2p - Two Pence

| Reverse | The Badge of the Prince of Wales. |

| Designer | Christopher Ironside |

| Alloy | Copper-plated steel |

| Diameter | 25.91 mm |

| Edge Thickness | 1.85 mm |

| Weight | 7.13 grams |

1p - One Penny

| Reverse | A portcullis with chains royally crowned. |

| Designer | Christopher Ironside |

| Alloy | Copper-plated steel |

| Diameter | 20.32 mm |

| Edge Thickness | 1.65 mm |

| Weight | 3.56 grams |

History of the Royal Mint

The following is reproduced from the folder which contains the Brilliant Uncirculated Coin Collection for the Millennium year 2000:-

3 Millennia

The Royal Mint lies at the heart of British Coinage. It has been responsible for the currency for well over a thousand years, there being an unbroken link from the scattered workshops of the moneyers of Anglo-Saxon London to the modern coining plant in Llantrisant, South Wales. Thus, form the silver pennies of Alfred the Great to the gold nobles of medieval kings, form that most renowned of coins, the gold sovereigns, to the new bi-colour £2 coin the Royal Mint can claim to span three millennia.

1st Millennium

Perhaps the most important milestone in the history of the Royal Mint can be associated with Alfred the Great. In 886 Alfred occupied London, already a "most renowned place and royal town", and there was a spectacular issue of silver pennies. From this point, minting in London passed permanently into the hands of the West Saxon kings. Alfred's grandson Athelstan decreed that there was to be "one coinage over all the king's dominion" and by 1000 AD a united England could boast a unified coinage. This unified coinage was not, however, the product of a single mint but of many scattered mainly in the southern half of the country.

2nd Millennium

Mints were then little more than blacksmith's shops. Communications were far from easy and, for the sake of his business, a merchant would not wish to be too far from a mint. But even though the mints operated independently, their moneyers had to be officially confirmed in office and licensed. After the Norman Conquest, the number of mints outside the capital declined and the London Mint came very much to the fore.

To The Tower

By 1279 the London moneyers had come together within the safety of the Tower of London. Soon Mint organisation adopted a more formal structure and its privileges were protected by Royal Charter. By the reign of Elizabeth I the Tower Mint was the only mint regularly in operation in England, and its success in replacing the debased money of Henry VIII and restoring the coinage to its rightful value is regarded as one of the major achievements of her reign. In fact the monarch herself is known to have visited the mint in the Tower to express her gratitude in person.

By now mechanisation was on the horizon and proof of what could be achieved by the new coining presses was provided by Briot's coins of Charles I and Blondeau's splendid portrait coins of Cromwell. Finally the restored Charles II, perhaps ashamed of the damning contrast between his coins and those of Louis XIV, authorised Blondeau to install machinery in the Mint and to "direct and instruct the Monyers in Coyning the Gold and Silver Moneys by way of ye Mill and press".

To Tower Hill

Mechanisation turned the Mint into a factory and, in time, its quarters within the Tower became more and more cramped. With the eventual application, thanks to James Watt, of steam power to the new processes, it was impossible for the Mint to stay on a site that was also an ordnance store. In 1810, therefore, it was transferred to purpose-built premises on nearby Tower Hill, where it could boast the "most beautiful and correct Mint machinery in the world".

To South Wales

Steam was to be replaced by electricity and coining presses as they became old by new. But it was the pressure of a vastly expended output coupled with the burden of producing huge numbers of new decimal coins that eventually led to the Mint's departure from the capital to a greenfield site in Llantrisant.

The new Mint was opened by Her Majesty the Queen in December 1968 and the transformation to a huge modern trading business was virtually complete.

3rd Millennium

Tody bi-colour, screen printed and gold-plated coins are already becoming commonplace and the United Kingdom has already seen its first hologrammed coin. Minting techniques continue to evolve and the new millennium will no doubt witness changes that are currently in the realm of science fiction.

Minting for the Millennium

The modern minting process is an unusual marriage of the most up-to-date technology and traditional craftsmanship. Trained engravers perfect the master tools used to produce dies for the coining presses, removing the tiniest of blemishes and sharpening details so that the designs are reproduced with the utmost clarity. Meanwhile, the metal is rolled to the required thickness and blank discs punched out in a blanking press. Softened and cleaned, washed and dried, these blanks are then passed to the coining presses and automatically fed between a pair of dies to be struck at speeds of up to 750 a minute.

In the case of collectors coins, special attention is given to the dies and blanks before they are brought together in the dust-free atmosphere of the Proof Coin Unit where, to ensure perfect clarity of design, each blank is struck at least twice.

| ...at the Official Issue Prices |

|

32 - 36 Harrowside, Blackpool, Lancashire, FY4 1RJ, England.

Telephone (44) - (0) 1253 - 343081 ; Fax 408058; E-mail: The URL for our main page is: https://24carat.co.uk | Web Design by Snoop |